Continuous operation

Oil flooded screw air compressors are designed for 24*7 quite operation year round.

Cost effective

Especially for applications requiring continuous and large volume of compressed air.

Higher efficiency

Oil significantly improves sealing and heat dissipation enhancing overall efficiency of compressor.

Quiet operation

These compressors operates at around 70 dB of noise which is quieter than reciprocating compressor.

Durable

Oil lubrication reduces mechanical wear , extending the lifespan of internal components.

Longer life

Oil flooded screw air compressors tend to have an average life span of 10-15 years, if maintained as recommended.

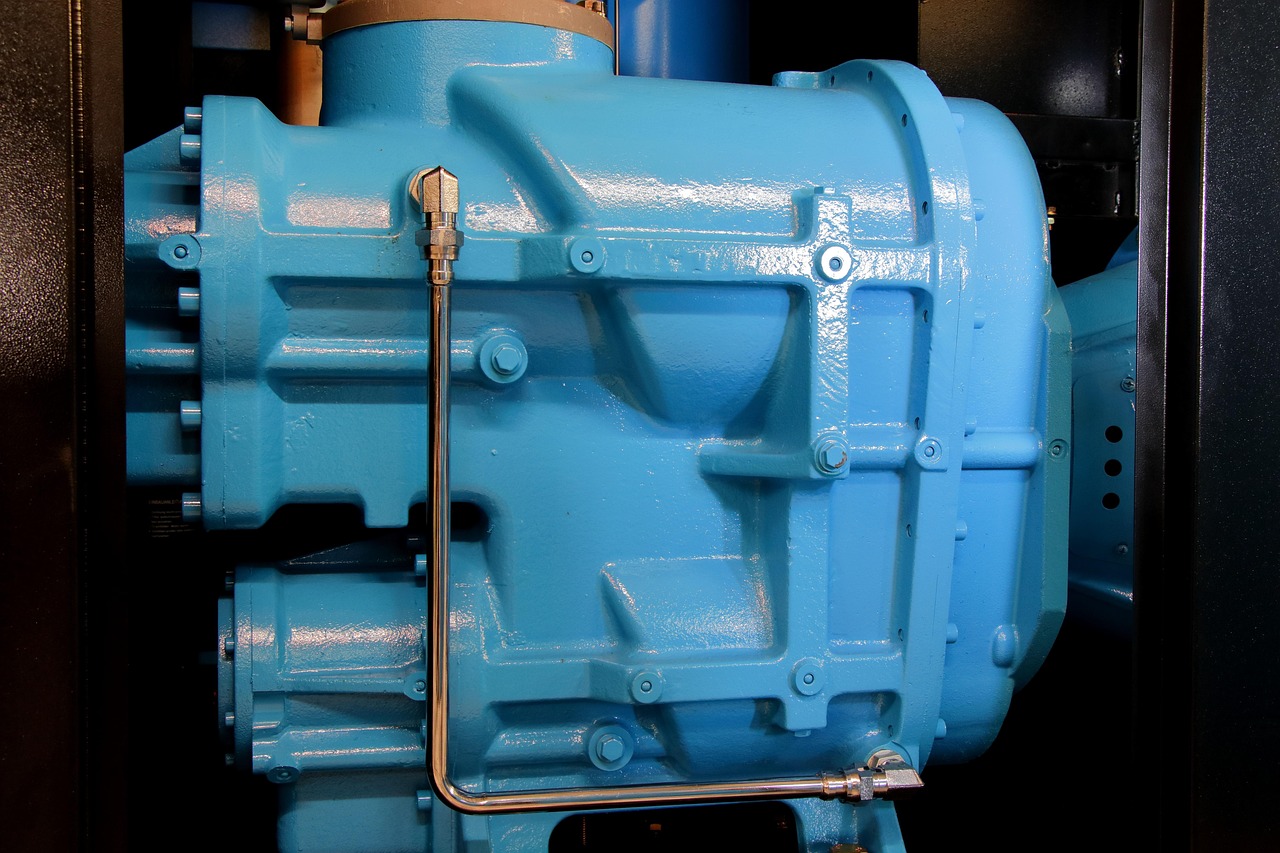

Oil-Injected Screw Compressor

Oil-injected screw compressor is a type of rotary screw compressor that uses oil in the compression process. Inside the compressor, two interlocking rotors spin at high speeds. As air enters the compressor, it gets trapped between the rotors and is compressed as it moves along the screws.

Oil-injected screw compressors are used in a variety of industries

Manufacturing

Powering pneumatic tools, conveyor systems, and automated machinery

Automotive

Spray painting, tire inflation, and powering impact wrenches

Food and Beverage

Though less common here due to oil contact, they’re still used in non-critical areas

Construction

Operating heavy-duty air tools and supplying reliable air in demanding environments

22 - 1560

cfm

10 - 335

hp

115 - 230

psi

230, 460, 575

Volts